In today’s rapidly evolving world, where clean and safe water is becoming increasingly scarce, the demand for efficient filtration systems has never been higher. One technology that has emerged as a game-changer in this field is the filter cartridge winding machine. This article aims to provide an in-depth understanding of how this innovative machine works and its significance in balancing standardization and customization.

The Functionality of Filter Cartridge Winding Machine

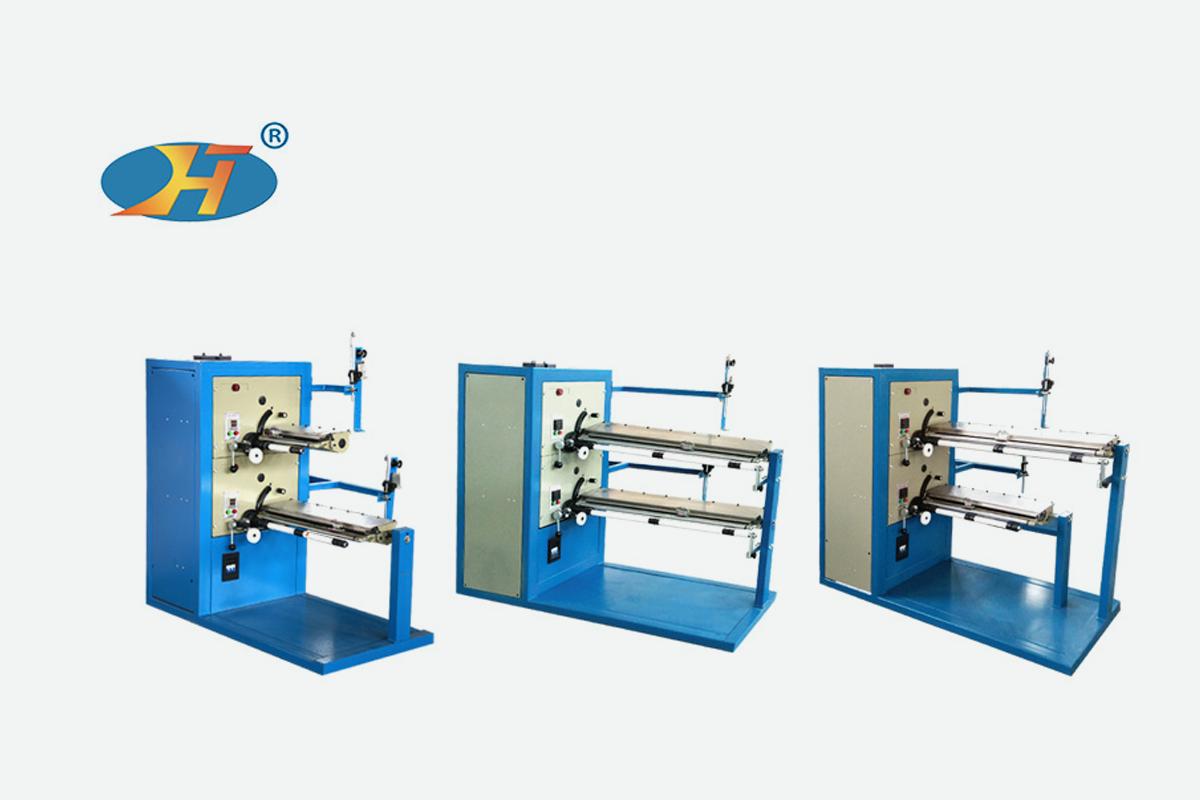

The filter cartridge winding machine is designed to automate the production process of filter cartridges used in various industries such as water treatment, pharmaceuticals, food processing, and more. It utilizes advanced technology to wind different types of filtering media onto a central core or support structure with precision and consistency.

This automated process ensures uniformity in the size, shape, and density of each filter cartridge produced. By eliminating human error and variability from manual production methods, it guarantees high-quality products that meet stringent industry standards.

Hongteng: A Leading Manufacturer

When it comes to reliable filter cartridge winding machines, Hongteng stands out as a trusted name in the industry. With years of experience and expertise under their belt, they have perfected their machines’ design to deliver exceptional performance.

Hongteng’s filter cartridge winding machines are equipped with state-of-the-art features like precise tension control mechanisms, adjustable speed settings, automatic cutting systems for accurate length control, and user-friendly interfaces for easy operation. These machines ensure optimal productivity while maintaining consistent quality throughout the manufacturing process.

The Role of PP Melt Blown Filter Machine

An integral part of the filtration system is the pp melt blown filter machine which produces melt blown filters – a key component used within many cartridges. This machine melts and extrudes polypropylene resin through a die, forming microfibers that are then blown onto a collecting screen to create a dense filter matrix.

The PP melt blown filter machine’s ability to control the fiber diameter and density allows for customization according to specific filtration requirements. It enables manufacturers to produce filters with varying levels of efficiency, pore size, and dirt-holding capacity, catering to diverse applications in different industries.

Conclusion

The filter cartridge winding machine has revolutionized the filtration industry by streamlining production processes and ensuring consistent quality. With Hongteng’s expertise in manufacturing these machines and the flexibility offered by PP melt blown filter machines, companies can strike the perfect balance between standardization and customization.

As water scarcity continues to pose challenges worldwide, investing in advanced technologies like the filter cartridge winding machine becomes crucial for meeting growing demands while maintaining high standards of filtration performance.