The increasing demand for sustainable agricultural practices has led to a significant interest in Organic fertilizer granule production lines. These systems not only enhance soil health but also contribute to environmental sustainability by recycling organic waste. In this article, I will analyze the intricacies of these production lines and their applications across various agricultural settings.

Understanding Organic Fertilizer Granule Production Lines

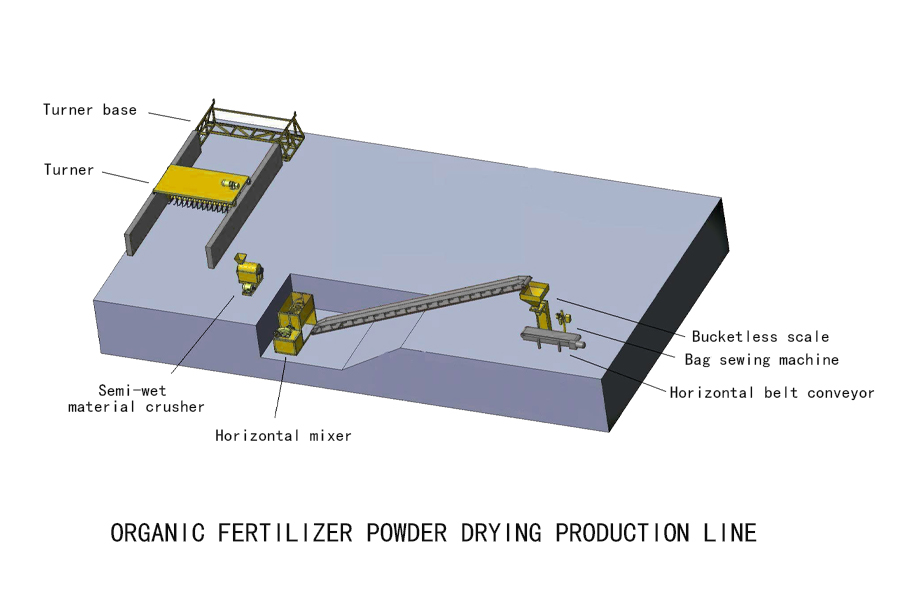

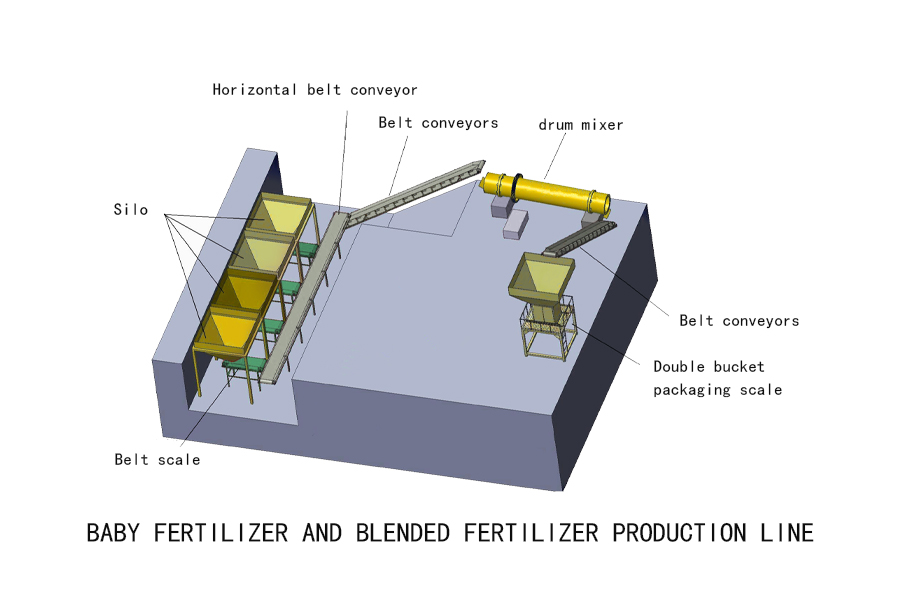

Organic fertilizer granule production lines are sophisticated setups designed to convert raw organic materials into nutrient-rich granules suitable for agricultural use. The process typically involves several stages, including composting, grinding, mixing, pelleting, and drying. Each stage is crucial for ensuring that the final product meets quality standards necessary for effective soil amendment. Moreover, these production lines can be tailored to accommodate different types of feedstock, making them versatile tools in modern agriculture.

Xincheng’s Role in Advancing Organic Fertilizer Technology

Xincheng has emerged as a key player in the development of advanced organic fertilizer technologies. Their innovative approaches focus on enhancing efficiency while minimizing energy consumption during the production process. By integrating state-of-the-art machinery with eco-friendly practices, Xincheng sets a benchmark for other manufacturers aiming to enter this growing market. Furthermore, their commitment to research and development ensures continuous improvement and adaptation to changing agricultural needs.

The Importance of Turner Composting Machines

A pivotal component within many organic fertilizer granule production lines is the turner composting machine. This equipment facilitates aerobic decomposition by turning over compost piles regularly; thus promoting optimal microbial activity essential for breaking down organic matter efficiently. The design of turner machines varies from stationary models to more mobile units capable of processing larger volumes quickly—each serving specific operational requirements within diverse farming contexts. Consequently, they play an indispensable role in producing high-quality compost that serves as a primary input material for subsequent granulation processes.

Conclusion: Emphasizing Sustainable Practices through Organic Fertilizer Granule Production Lines

The exploration of organic fertilizer granule production lines reveals their critical importance not only in enhancing crop yields but also in fostering sustainable agricultural practices worldwide. As we continue navigating challenges posed by conventional farming methods and climate change impacts on food security, investing in such technologies becomes imperative. Ultimately, embracing innovations like those offered by Xincheng alongside efficient equipment such as turner composting machines will pave the way toward more resilient agro-ecosystems.